Integrating Sphere Build Process

Author: Nikoli Cooper, UA undergraduate TIMESTEP Apprentice.

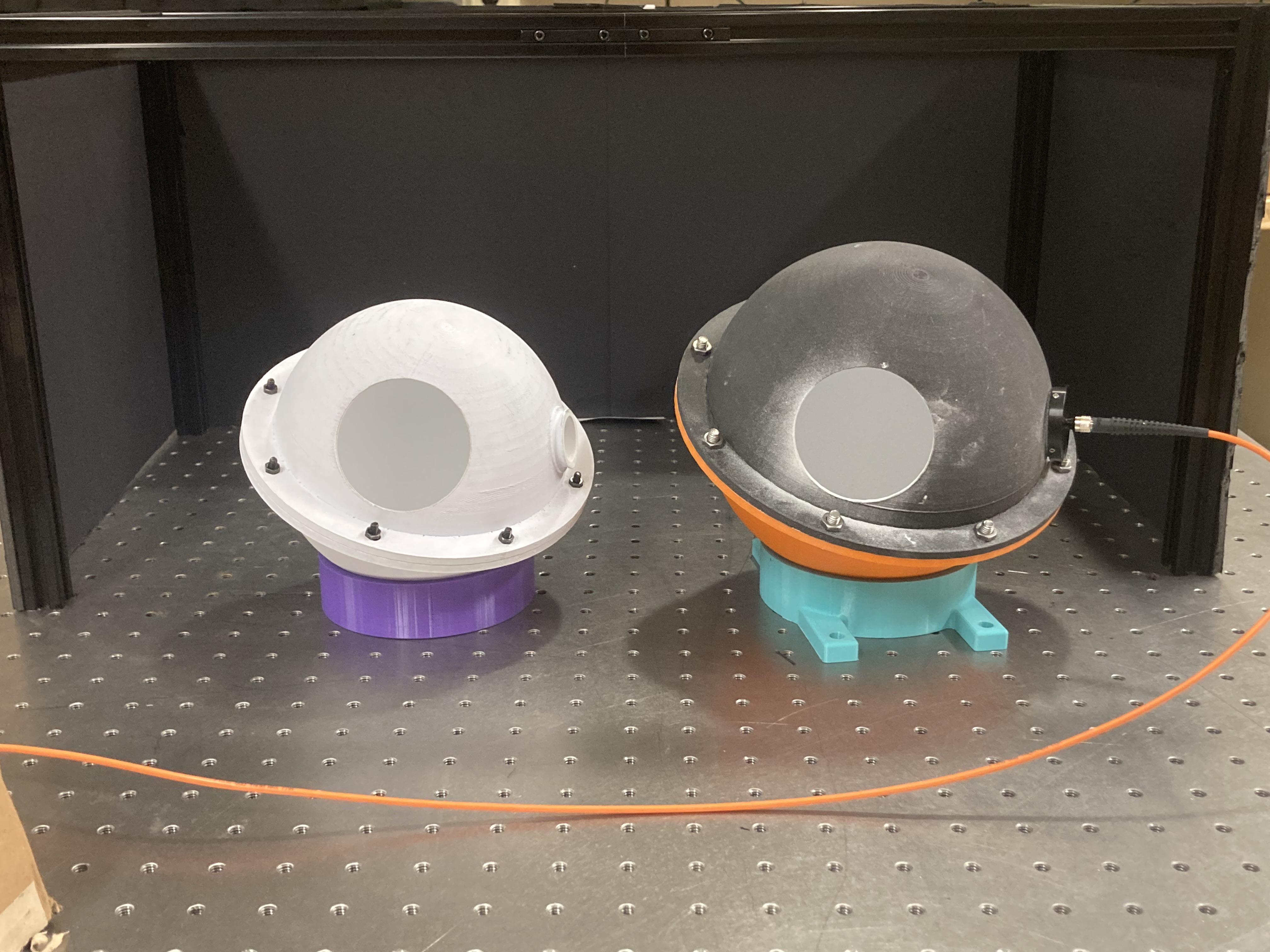

Commercial Integrating Spheres on the market are high quality, yet expensive. A 6” diameter can cost upwards of $2000. In order to minimize the cost of CMOS characterization, we have devised a procedure to create our own small Integrating Sphere (up to 7” diameter) from scratch.

This characterization is distinct from sensor characterization performed at the UA Imaging Technology Lab discussed in other blog posts (e.g. https://uasal.github.io/testing/sensor_reports/).

Design Process

We designed one 6” and one 7” diameter Integrating Sphere in SolidWorks with a few design criteria:

- Surface area covered by ports must be 5% max, from Building an Integrating Sphere

- Spheres must be 3D printable on a Prusa mk4. (7” max diameter, with flange)

- Outlet port must be able to cover the majority of a Sony IMX455 (1.7” diagonal), and the inlet port must be set up for an optical fiber.

- A baffle must block light from directly exiting from the inlet port.

Fabrication

- The two Integrating Spheres were 3D printed on a Prusa mk4 in PLA. They both have a 2.5” diameter outlet port, and a 1” diameter inlet port for use with Edmund Optic’s 1” SMA adapter for optical fiber attachment. Each sphere was printed in two halves and connected via a flange with 8 M6 bolts.

- Following printing, the Spheres were rigorously sanded with 60 and 80 grit sandpaper to remove imperfections and texture from the 3D printing process. Any small holes in the inside surface were coated with Elmer’s glue to prevent paint leakage.

- 2 coats of aluminum silver paint were applied first to make the spheres light-tight and to reflect light above 900 nm, where the white wall’s reflectivity starts to drop off. Both spheres used a total of 30 ml of silver paint.

- 6 coats of Avian B white wall with Barium Sulfate were used as the main high-reflectivity coating. Paint was applied in thin layers and diluted with water (around 50%) for airbrush application. Coating both spheres used around 1/2 - 2/3 of a 250 ml bottle of Avian B.

Testing

The main ways to evaluate an Integrating Sphere are by its sphere multiplier and its reflectance. The calculation methods for these numbers are highlighted in this paper.

Reflectance is calculated from the sphere multiplier and geometric conditions of the sphere itself. The sphere multiplier is given by:

Mₛ = (output flux / input flux) × (sphere surface / input port surface)

And reflectance is given by:

Rₛ = 𝟷 / ( (𝟷 / Mₛ) + 𝟷 - port fraction )

The only unknown value here is output flux.

1. Calculating Output Flux

The output flux is measured using a PixeLINK PL-D753MU-BL CMOS sensor.

- The optical fiber is pointed at the sensor from an arbitrary distance. Broadband (400 - 2200 nm) light was used.

- The sensor captures an image at 3 ms exposure, yielding an image within its dynamic range.

- Astropy is used to calculate the average signal from the image.

- The fraction of the surface of the light cone at the sensor plane that the sensor covers is taken as k.

- Then, input flux × k = i, where i is the flux required to illuminate the sensor to the average signal measured.

- A second image is taken through the integrating sphere at the same exposure time.

- The ratio between the average signal with and without the integrating sphere is r.

- The fraction of the output port covered by the sensor is f.

- Error calculated as Standard Deviation from 10 separate output flux measurements per sphere. Thus, the output flux is calculated as:

(1 / f) × r × i = output flux

From here, we can directly compute the sphere multiplier and reflectance.

2. Results

6” Sphere:

- Sphere multiplier: 7.06

- Reflectance: 91.6%

- Standard Deviation in sphere multiplier: 0.134

7” Sphere:

- Sphere multiplier: 8.07

- Reflectance: 92.0%

- Standard Deviation in sphere multiplier: 0.145

Total Cost for a 6” and a 7” Integrating Sphere:

| Item | Cost ($) |

|---|---|

| Avian B Paint | 280 |

| PLA Filament | 25 |

| Silver Paint | 20 |

| Airbrush | 20 |

| SMA Adapter | 285 |

| Hardware Set | 10 |

| Total + tax | 704 |